MODEL : DL-743

Automation solutions to shorten the socks knitting process

DL-743

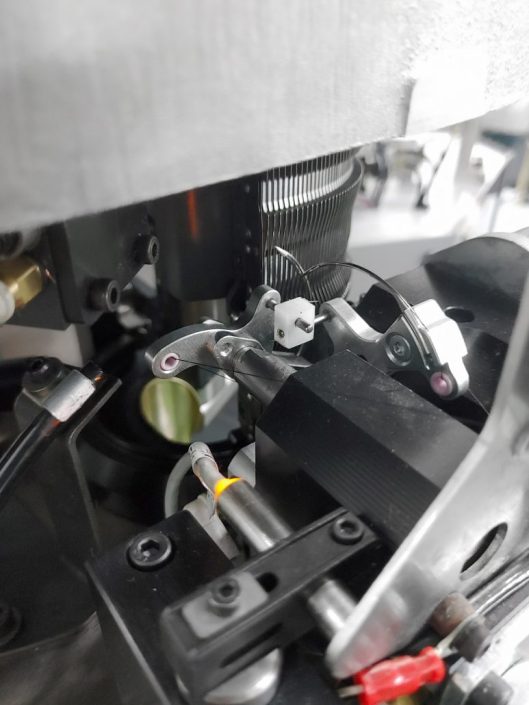

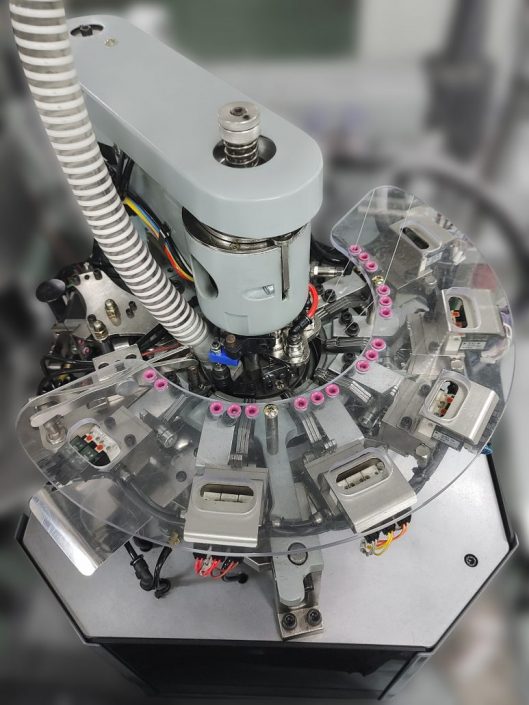

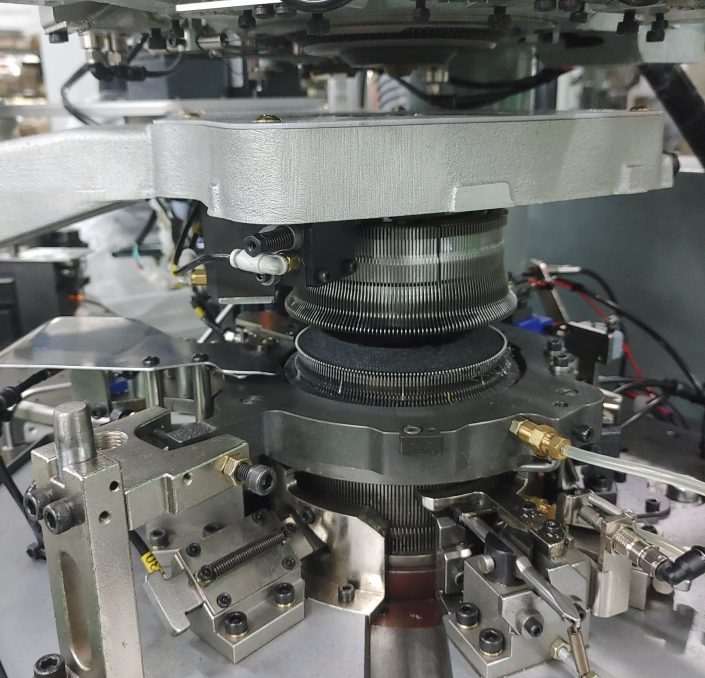

Automatic toe-linking device D4S

The D4S is a fully automatic toe-linking device for sock knitting machine. It is based on a completely revolutionary idea for automatically linking socks directly on the knitting machine.

Major Features

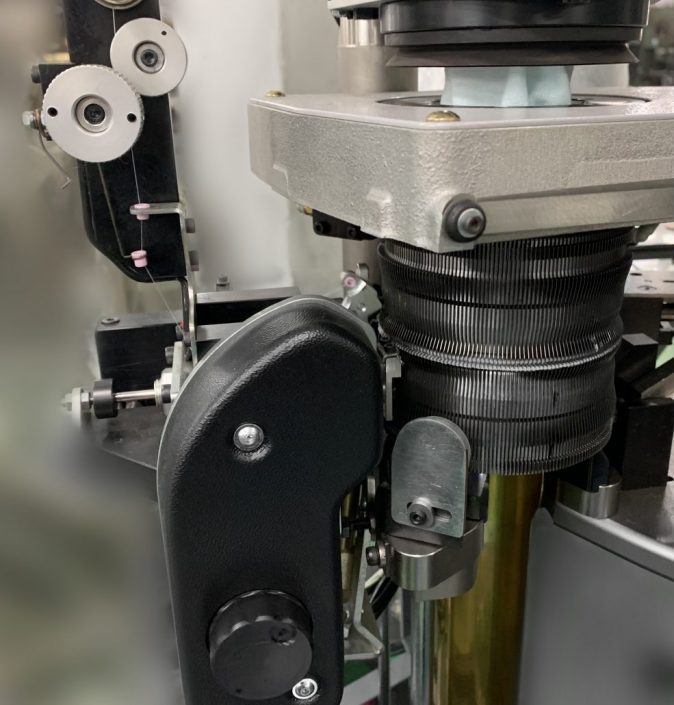

- 7 Feed

Knitting with total 17 colors is possible by adding one more Feed to the existing 6 Feed.

Adding colors, it is possible to implement various designs and to manufacture socks of higher quality by increasing the density of socks structure, and it is also possible to knit the fine patterns comparing with the existing socks. - Electronic control system 2900SL

The 2900SL system is compatible with most commercially available operating systems and versions, such as ARM processor architecture or Linux-based real-time operating systems

High safety/reliability, even in challenging environmental conditions

A minimum of circuit boards and wired connections allows the fast recovery

The housing and the control panel can be customized to meet specific customer needs - Programming systems DData and DStyler

– DData and DStyler are two comprehensive, innovative software packages for programming knitting patterns and for process monitoring and data recording during knitting.

– DData – a real time remote control system for your hosiery machines. Connected via Ethernet with TCP-IP protocol, the software collects and displays all events during the production process in real time.

– DStyler – a flexible graphics application for designing knitting pattern programs especially for socks and for knitting machines with medium diameters and hosiery knitting machines. It features versatile programming of knitted patterns for various knitting machines, user-friendly interface runs on standard Windows platforms and possibility of graphic visualization.

Key Benefits

- Significantly higher productivity in sock manufacturing

- Short idle time of the machine for removal of the finished knitted socks

- Rapid payback thanks to excellent price/performance ratio

- Easy adaptable to various diameters

- Electronic control system 2900SL

- This electronic control system for sock and seamless knitting machines features easy customizing, configuration, and programming.

- With these unique high-tech controllers you react quickly to market demands steadily delivering competitive final products.

Options

- Yarn sliding control sensors